TECH TIPS

Slow Startup in the Morning

If you have a machine that seems to move in slow motion in the mornings and has Elevator Jam error codes on the control box screen

If you have a machine that seems to move in slow motion in the mornings and has Elevator Jam error codes on the control box screen, check the pulleys on the front distributor shaft.

Usually when this happens, you will notice that the crossover and main distributor belts are turning at normal speed. The outside return belts, elevator and transport band will be moving slowly.

If this is happening, it is usually caused by oil and dirt on the inside surface of the belt and on the inside surface of the pulleys on the front and rear distributor shafts.

Clean the circumference of the belts and clean all 8 pulleys.

In some cases, these belts become stretched and will not have enough tension to drive the rear distributor shaft and will need to be shortened or replaced.

The Alignment Assignment

To easily line up the pin in the Clutch drive disc and the bronze bushing, first determine the

To easily line up the pin in the Clutch drive disc and the bronze bushing, first determine the location of the pin as shown in the photo.

Then rotate the bushing to the mirror image of the pin.

Align the dot on the edge with the hole in the bushing and gently slide the drive disk onto the splines. If the pin does not go into the hole, pull the disk back a little and turn the bushing slightly.

Groovy Is Not Groovy

Any time the magnetic clutch is removed from the shaft, inspect the condition of the surface of the Pin Wheel drive pulley.

Any time the magnetic clutch is removed from the shaft, inspect the condition of the surface of the Pin Wheel drive pulley.

A grooved surface will reduce the driving force from the magnetic clutch. Keep a spare pulley with a good surface on hand and have the face of the removed pulley trued by a local machine shop.

Is Your Center “Noteworthy?”

Leaving a note for the maintenance staff is not as simple as it might seem. A note should contain as much detail as possible.

Leaving a note for the maintenance staff is not as simple as it might seem. A note should contain as much detail as possible. Add a date, time, and name of who wrote the memo, and it will be almost perfect.

“Air conditioner making a funny noise” might be enough for some center. But centers with multiple units will need more detail.” On Monday at 7:30PM, the air conditioner over lanes 23-28 was squealing when it started up. Noted by Bob”.

The latter statement not only has the location of the problem, but a description that will lead to a shortened troubleshooting time. This same logic should be applied to any description in your bowling center. Location is paramount, followed by as much information as possible.

Legible handwriting is of great importance. I have spent many a morning trying to decipher a note from a fellow employee with poor penmanship. Numbers need to be carefully written. No one wants to start troubleshooting in the wrong place.

You must realize that the rest of the staff probably does not have the maintenance training that you do. Nomenclature might be a little off from the terms you use.

Notes might come from the cleaning crew, porters, desk people, food and beverage, or even a bowler. Of course, notes from the manager or owner are a high priority.

Where the note is place is of extreme importance. A note does no good if it is never read. At some bowling centers, a note for the mechanic left on the back part of the front desk., would be lost in a sea of post-it notes, recap sheets, and fundraiser flyers.

If there is a matter of high importance that needs to be attended to immediately, the note should be placed where the mechanic can see it the moment he walks into the building. At my center, that was on the door leading behind the pinsetters.

After getting a note from a fellow employee regarding a problem, I prioritize the noted problem along with my normal daily duties. An exit light that has a burned-out lightbulb is low on the list when the ice machine is not working.

Safety hazards should be high on the priority list. The well-being and safety of customers and employees should never be compromised by a lower priority task.

One thing to keep in mind is that a high priority item to one person might be low to another. Multiple notes about the same problem can cause some conflict between employees. Good communication will resolve these conflicts by allowing the employee who noted the issue to know that the problem is on the “to do list”.

Keep a folder to file notes in. This allows for quick access if any questions arise regarding the time and date of a maintenance problem.

To get good information, you need to give good information. Let the people you work with know exactly how you would like a note written. Some places even have pre-made forms for maintenance issues.

Maintenance of your center is everyone’s job, and communication is the key to making the best experience for your customers.

T-Band Tension Adjustment Jam Nuts

Use a nylon filled lock nut to ensure the adjustment nut doesn’t come loose.

This tip comes from KMK member Amano Ho.

Use a nylon filled lock nut to ensure the adjustment nut doesn’t come loose.

Tools of the Trade

Here is an awesome Tool of the Trade submitted by KMK member: Mark Miller. It is important to keep the kickbacks tight to the accelerator box but reaching the bolts for the barrel nuts is a tough task.

Here is an awesome Tool of the Trade submitted by KMK member: Mark Miller

It is important to keep the kickbacks tight to the accelerator box but reaching the bolts for the barrel nuts is a tough task. Mark made his own super long extension to reach the bolts using a long piece of 3/8 square stock.

For those who are not as handy as Mark, here is a link to an extension:

V-8 Tools 98036 $36.65 1/2" to 3/8" Drive Impact Extension Adapter SAE | Zoro.com

Halo, Is it Me You’re Looking For?

When removing the Turret Halo Ring, use a fine-tip black marker to note the current adjustment.

When removing the Turret Halo Ring, use a fine-tip black marker to note the current adjustment. Do this on both sides. This will make reinstallation much easier.

Don’t Get Tong Twisted

Here is an easy way to tell forward facing tongs (1,4,5 and 6) from the rearward facing tongs (2,3,7,8,9 and 10)

Here is an easy way to tell forward facing tongs (1,4,5 and 6) from the rearward facing tongs (2,3,7,8,9 and 10)

A2 Electrical Diagram

This tip has been provided by Marty Murphy. His unbelievable interactive electrical schematic allows the user to isolate specific wiring paths for an easier visual understanding of the circuitry inside of the electrical box of an A2 pinsetter. Marty’s mentor created this, and Marty reached out to him for his approval to post on our site.

Tools of the Trade

Working on the pinsetter can be a challenge without the correct tools. Often the tight confines of the machine require tools that are specially made for that application.

Working on the pinsetter can be a challenge without the correct tools. Often the tight confines of the machine require tools that are specially made for that application. Here is a list of some of the tools that will make your job more efficient and might save your knuckles. (Links are provided on some photos to assist you in finding some specialty items.)

1. Scissor removal: A shortened 15/16 wrench will help a great deal when removing a set of scissors from a Model A or A2 machine.

2. Lower Ball Wheel Guide Roller: Removing the roller from the shaft can be a troublesome task. Some mechanics use a Ball Joint removal tool (commonly know as a “Pickle Fork”)

3. Lower Ball Wheel Guide Roller Shaft: A shortened ½ hex key will fit into the bolt behind the pinwheel roller.

An alternative to #3 from our friend William Pike:

4. Deck Jam Switch Checker: Every center should have one of these. The deck jam switch is key to prevent damage to your gearbox. There are several styles of this tool.

5. Deck Jam Tube Spring Compressor: These tools make changing the pin and cable a safe and quick job.

6. A good flashlight with a magnetic base and or hanger: A flashlight with a magnetic base can act as an extra hand when working in low light areas. LED flashlights extend battery life.

7. Battery operated hand tools: The portability of battery powered tools makes them perfect for use on the pinsetter. Drills, angle grinders, saws, and even shop vacuums will make life much easier when working on your equipment.

8. Lift Rods: The Bench Mount Lift Rod Tool PPP-LRBM is a great tool for holding the lift rods securely. With the lift rods attached to the tool, ball lift arm maintenance and rod cover replacement can be done easily.

9. Ratcheting screwdriver: Save time and your wrist with a ratcheting screwdriver.

10. A good set of manual gear pullers: A good set of pullers will save time and money. You can pull bearings and gears when rebuilding pinsetter assemblies.

11. Universal Joint socket extensions: Many of the areas of the pinsetter are hard to reach. Universal Joint extensions help access the difficult hardware.

12. Remote Continuity Tester: Check wires for continuity remotely. Save steps and time!

13. A great addition to a toolbox is a bottle of instant adhesive. (Commonly know as Super Glue). It is great for quick temporary repairs and can be used to hold troublesome hardware in place during assembly.

14. A label maker can be handy. From categorizing parts containers to labeling wires during an electrical job, properly labeled items will speed up repairs and reduce confusion.

15. A hydraulic press is a necessity if you are going to be doing any of your own gearbox work. Be certain to obtain a press with ample capability and learn to operate it in a safe manner.

16. A set of picks will help with numerous projects. Removing a seal from a bearing is easy using a pick.

17. A brass hammer is great for jobs where a steel hammer might cause damage.

Do you have a “Tool of the Trade”? Email us at: mechanicsklub@kegel.net

The Lockdown

When working on your equipment, always check your stock of fasteners before beginning a project. Not much is as frustrating as finding no replacement hardware to finish a repair.

When working on your equipment, always check your stock of fasteners before beginning a project. Not much is as frustrating as finding no replacement hardware to finish a repair.

Check the parts book for the sizes of hardware needed and have it on hand so your repair or rebuild will be complete.

Some hardware can be reused if still in good condition and some should have new fasteners installed every time it is reassembled.

Examples of reusable hardware are: bolts, flat washers, and nuts.

Some locking hardware can be reused a few times. Nylon filled nuts will gradually loose the gripping power of the insert and might only be useable 2-3 times. Split lock washers can be used a couple of time if there is still a definable split in the washer. (See photo)

Internal and external toothed lock washers should be replaced after 1 use, as the teeth are designed to flatten just once.

“X” washers are dependent on the application, but in general should be replace after 1 use if possible.

Most push on fasteners are designed to be used once and are usually are misshapen or destroyed during removal.

In an emergency repair, the reuse of hardware may be the only option. Replace it when time and inventory allow.

Rake Hook, Take a Look

If you are having problems doing the rake hook adjustment or have been breaking rollers on the rake hook cam follower, Check the following:

RAKE HOOK LINK

If you are having problems doing the rake hook adjustment or have been breaking rollers on the rake hook cam follower, Check the following:

The Sweet Spot for Shovels

Over the years, I have found that there is a “sweet spot” to remove shovels from the chains. One still must use care not to not push the chain too far.

Over the years, I have found that there is a “sweet spot” to remove shovels from the chains. One still must use care not to not push the chain too far. If you go too far the shovels below the one you are trying to remove will drop off their pins. Shovels falling like this can break off the pin on the opposite side.

I position the shovel as shown in the photo. I carefully push the chain outward just enough to remove the shovel from the pin. This measurement can vary depending on chain stretch.

The Old Switcheroo

Do not be intimidated by the error codes on the electrical box display. Except for the BA code, every code involves a switch.

ERROR CODES

Do not be intimidated by the error codes on the electrical box display. Except for the BA code, every code involves a switch. Either a switch did not close, or a switch did close.

The code tells you which switch. From there you can trouble shoot why the switch did or did not close.

The BA code (Ball Accelerator) code indicates that the Accelerator motor has over heated or the wiring is not intact.

Bowling Avengers…Assemble!

When it comes to speedy repairs and quick maintenance, having assemblies pre-made and ready to be installed is a must.

When it comes to speedy repairs and quick maintenance, having assemblies pre-made and ready to be installed is a must. This allows for the replacement of many hard to reach parts to be done on the workbench.

While some assemblies might initially cost more than the commonly replaced parts inside, the time savings are significant. Many assemblies can be replaced by lesser skilled employees, allowing your equipment to be back in operation quickly.

Major assemblies can be used as teaching tools to train future techs about the parts inside and how they interact. Rebuilding assemblies is a great way to learn about your equipment.

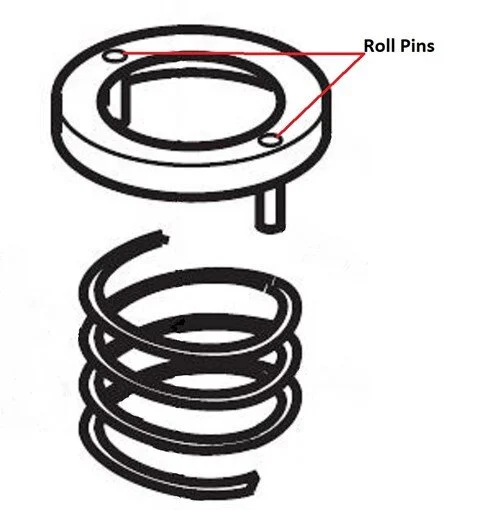

Turret Clutch Spring Guide

When reassembling the turret clutch, be certain that the roll pins in the spring guide are below the surface of the spring retainer.

When reassembling the turret clutch, be certain that the roll pins in the spring guide are below the surface of the spring retainer. Also verify that the roll pins are going into the holes in the turret clutch slide plate.

The Ring of Death

After removing the indexing cam, the 5-pin center chute, and the turret wire assembly, remove only the bolts shown in green.

TURRET RING ASSEMBLY

After removing the indexing cam, the 5-pin center chute, and the turret wire assembly, remove only the bolts shown in green. This will allow the turret ring assembly to be removed without releasing the loose ball bearings. The assembly can then be rebuilt on the workbench. Removing the bolts shown in red will release 149 ball bearings onto the workbench! Be prepared to catch them!

VIEWED FROM ABOVE

The Big Chill

If you have not winterized your center yet, your running out of time. The cool breeze of November is upon us

If you have not winterized your center yet, your running out of time.

The cool breeze of November is upon us, and while winter weather is usually good for business, since it gets our customers to think about indoor recreation, it requires us to make changes in how we approach maintenance.

Contacting your snow removal company before too much of the white stuff piles up can have a huge benefit. Start by determining how much snow needs to accumulate before its removal is needed. This allows you to schedule an automatic plowing of your parking lot if snow levels meet your predetermined quantity.

The location of speed bumps and parking blocks should be noted, and that information given to the snow removal service. If the weather is holding, you might want to fix potholes and large cracks in the pavement now before ice and cold digs them deeper.

Some centers have their own plowing equipment. This should be checked and ready to roll prior the first snowfall. Hydraulic lines should be inspected and repaired, as necessary.

Stock a supply of ice melting product. A method for distributing the ice melt should be discussed and implemented. Something as simple as a coffee can with holes in the bottom or a "whirlybird" style lawn spreader can save considerable money by dispensing the ice melt in an even pattern.

Locating your center's snow removal tools before too much of the white stuff comes down can keep tempers from flaring. No one wants to spend a cold, wet morning hunting for the snow shovel. Inspect the blade, handle and rivets for wear and tear. Replace if it looks like it might come apart under the load of a big scoop of wet snow.

The appropriate mats, placed on the floor inside of the doors, can capture a lot of ice and snow before it makes its way onto the concourse. A wet-dry vacuum can be used twice a day or more to keep the mats from becoming water-logged.

Keep an-up-to date list of league secretaries near the phone if blizzard conditions require the cancellation of league play. And do not forget to call the staff to keep them from venturing out onto roads when the center is closed or slow due to the weather.

By now you are probably seeing your energy costs spike up because of more expensive heating oil and natural gas. Do not be tempted to tweak your thermostat every time a customer complains about being cold. Remember, you are trying to heat a very large area. A change of just a few degrees can make the heating unit run for several minutes.

Your heating system needs to be operating as close 100 percent as possible. Dirty filters, clogged burners, loose belts, and bad heat exchangers can rob the unit of efficiency. Have your units checked now if you did not do it this fall.

The used of portable space heaters should be limited. While these units do provide a quick warm-up for a small space, they are also dangerous. Hundreds of fires each year are caused using space heaters.

The cost of heating a bowling center can literally go through the roof, if the insulation is old or has sagged away from the roof decking. Have your center inspected and reinsulated where and when it is needed.

Speaking of the roof, leaks should be addressed immediately. Th safety of both your customers and employees is at risk when water is dripping onto the floor. Have your roof checked in the autumn, to prevent a mid-winter disaster.

Your roof will bear the weight of the snow that falls. Most bowling center roofs do not have enough pitch to them allow the snow to slide off. If the forecast calls for an unusually heavy amount of snow, be ready to recruit some friends and shovels. By removing this extra weight, you just might keep your center open. Last winter, three centers were forced to temporarily close in Colorado due to sagging roofs.

Lane conditions will change with the arrival of colder air. The combination of a cold lane surface and the heating units cycling on and off, can make the lanes play differently.

The cleaning and conditioning supplies, as well as the machine used to dress the lanes; should be stored in a room temperature environment. Many lane conditioners are sensitive to cold, becoming thicker as the cold creeps into the building. Cleaners can be more effective when kept warm.

In many centers, the lane maintenance machine is stored next to an outside wall. This practice can lead to some very strange lane conditions. The settings that brought a great scoring pattern before are now producing unhappy bowlers. Another cold weather concern is the pinsetter area. Frigid temperatures behind the center can lead to early pin failure, slow operating machines (due to thickened oil in the gearboxes) and a cranky mechanic.

Maintenance is difficult enough to do, but when there is no heat on a frosty morning, it's almost impossible to get the motivation to touch a wrench. While it might seem like a costly luxury to some centers, the comfort of the maintenance staff should be a consideration. I have worked in back areas where a cup of coffee would freeze solid in a few hours. Trust me, I did the required work in a hurry!

By being prepared for the onset of winter, we can provide a safe, comfortable environment for our customers and employees. Paying attention to the weather can prevent major problems regarding every phase of the bowling business.

Watch your local forecast, consult the Farmer’s Almanac, and break out your thermal underwear. Winter is coming!

Which Way Is Up?

When beginning to work on pinsetters, there can be some confusion regarding front, rear, left and right. Both the parts and the service manual will use these references and knowing the differences can save time and money.

In almost all cases, the designation of left and right will be from the bowler’s point of view.

When beginning to work on pinsetters, there can be some confusion regarding front, rear, left and right. Both the parts and the service manual will use these references and knowing the differences can save time and money.

In almost all cases, the designation of left and right will be from the bowler’s point of view. Front and rear also is from the view of the bowler, with the farthest away being rear and the closest being front. In some rare cases there may be a reference to 7 pin or 10 pin side.

Clockwise and counterclockwise is defined by looking from the left side or from the top of the machine looking downward.

By knowing how the machine is oriented, you can do adjustments faster, order parts correctly and convey information more efficiently.